Introduction:

In today’s industries, many safety precautions and types of emergency equipment must be used to protect and ensure the health of employees. Although regulations and standards, personal protective equipment, and safety training are used, accidents still happen. Accidents involving hazardous chemicals can be especially severe. Employees who manufacture hazardous chemical products are at risk, of course. Hazardous chemicals can also affect people who work in food industries, or with cleaning solutions, and in manufacturing industries and service establishments.

Eyewashes and safety showers were developed in response to the increased use of hazardous chemicals. Eyewashes and safety showers are emergency systems used in both public and private industry to protect an employee from injury in case of contact with hazardous chemicals, chemical compounds or fire.

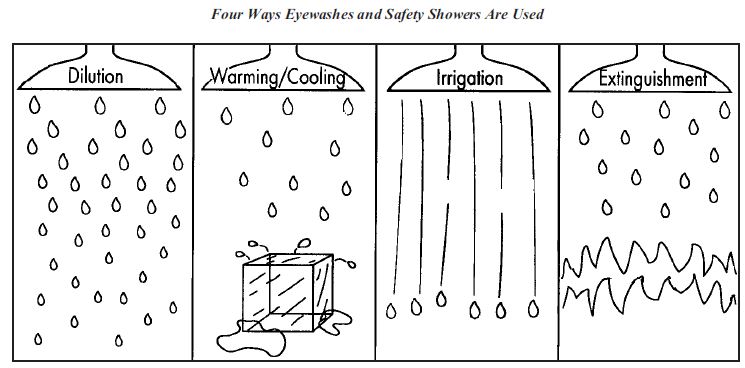

The four basic ways these safety systems are used (see Figure 1) include:

1. Dilution—diluting the chemicals that are on the skin or in the eyes to a nonharmful level.

2. Warming/cooling—warming or cooling the body or eyes because of a change in temperature due to chemical exposure.

3. Irrigation—flushing the chemicals out of the eyes or off the skin.

4. Extinguishment—putting out fires of clothing on the body.

The selection of emergency eyewash and shower equipment is often a complicated process. In addition to addressing design and engineering issues, specifiers must be aware of regulatory requirements and compliance standards. A common reference point when selecting emergency

equipment is ANSI/ISEA Z358.1, “Emergency Eyewash and Shower Equipment.” This standard is a widely accepted guideline for the proper selection, installation, operation and maintenance of emergency equipment.

To assist specifiers in understanding the provisions of this standard, Guardian Equipment has prepared this ANSI Compliance Checklist. In this Checklist, we have summarized and graphically presented the provisions of the standard. This Checklist can serve as a starting point for designing emergency eyewash and shower systems.

Legal requirements:

The Occupational Safety and Health Act of 1970 was enacted to assure that workers are provided with “safe and healthful working conditions.” Under this law, the Occupational Safety and Heath Administration (OSHA) was created and authorized to adopt safety standards and regulations to fulfill the mandate of improving worker safety.

OSHA has adopted several regulations that refer to the use of emergency eyewash and shower equipment. The primary regulation is contained in 29 CFR 1910.151, which requires where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”

The types of equipment addressed by the ANSI standard include:

Definitions:

- Emergency shower. The emergency shower is “a unit that enables a user to have water cascading over the entire body.” This unit is used for general irrigation of the body and although it can be used to rinse the face, the unit is not meant for flushing of the eyes.

- Eyewash. The eyewash is a unit that supplies fluid to irrigate and flush the eyes.

- Personal eyewash. The personal eyewash is “a supplementary eyewash that supports plumbed units, self-contained units, or both by delivering immediate flushing for less than 15 minutes.” The major difference between self-contained or plumbed and personal eyewash equipment is that the self-contained or plumbed one must have at least a 15-minute supply of water while the personal units have less than a 15-minute supply. Because of this, the personal eyewash is used on the site for immediate flushing and while the victim is moved to another unit. Irrigation should continue once the victim reaches the other unit.

- Eye/face wash. This device is “used to irrigate and flush both the face and the eyes.”

- Hand-held drench hose. This arrangement is “a flexible hose connected to a water supply and used to irrigate and flush eyes, face, and body areas.” With this unit it may be necessary for another person to hold the hose to allow the victim to hold his or her eyes open.

- Combination unit. The combination unit combines a shower with an eyewash or eye/face wash, or with a drench hose, or with both into one assembly.

- Plumbed unit. A plumbed unit is permanently connected to a potable water source.

- Self-contained unit. A self-contained unit is not permanently installed and must be refilled or replaced after use.